Need A Part Machined? CALL NOW

Capabilities Precision Plant list In-House Materials

We are very passionate about our ability to offer small components with precise dimensional tolerances, consistenty and with repeatability - it's what we do best, and is why our customers return to us time and again.

| Diameter TolerancesWe are able to achieve ±10µm tolerances on diameters from below Ø0.5mm and up to Ø30mm. |

Our machine shop houses eight Sliding Head Lathes for precision machining incredibly accurate and complex parts down to 0.5 mm in diameter to within 10 micron tolerances. These sliders sit alongside our Doosan Puma Turning Centre for producing larger parts up to 65mm in diameter and CMZ TX52 Y3.

Citizen L20X

| Machine Type: | Sliding Head |

| Max. Diameter: | 25mm |

| Bar Feeder: | 3 metres |

| Tooling Stations: | 30 |

Citizen L20X  |

|

Star Micronics SB-12-R

| Machine Type: | Sliding Head |

| Max. Diameter: | 12mm |

| Bar Feeder: | 3 metres |

| Tooling Stations: | 23 |

Star Micronics SB-12-R  |

|

Star Micronics SB-16

| Machine Type: | Sliding Head |

| Max. Diameter: | 16mm |

| Bar Feeder: | 3 metres |

| Tooling Stations: | 15 |

Star Micronics SB-16  |

|

Star Micronics SR-20-RIV

| Machine Type: | Sliding Head |

| Max. Diameter: | 20mm |

| Bar Feeder: | 3 metres |

| Tooling Stations: | 27 |

Star Micronics SR-20-RIV  |

|

Star Micronics SR-20J

| Machine Type: | Sliding Head |

| Max. Diameter: | 20mm |

| Bar Feeder: | 3 metres |

| Tooling Stations: | 30 |

Star Micronics SR-20J  |

|

Star Micronics SR-32J

| Machine Type: | Sliding Head |

| Max. Diameter: | 32mm |

| Bar Feeder: | 3 metres |

| Tooling Stations: | 27 |

Star Micronics SR-32J  |

|

Star Micronics SR-32J

| Machine Type: | Sliding Head |

| Max. Diameter: | 32mm |

| Bar Feeder: | 3 metres |

| Tooling Stations: | 27 |

Star Micronics SR-32J  |

|

Star Micronics SR-32J

| Machine Type: | Sliding Head |

| Max. Diameter: | 32mm |

| Bar Feeder: | 3 metres |

| Tooling Stations: | 27 |

Star Micronics SR-32J  |

|

Doosan Puma 240-MS

| Machine Type: | CNC Lathe |

| Max. Diameter: | 65mm |

| Bar Feeder: | 1.5 metres |

| Tooling Stations: | 24+ |

Doosan Puma 240-MS  |

|

CMZ TX52 Y3

| Machine Type: | CNC Lathe |

| Max. Diameter: | 50.8mm |

| Bar Feeder: | 1.5 metres |

| Tooling Stations: | 36 (12/turret) |

CMZ TX52 Y3  |

|

All of our machines have sub—spindles with driven tools offering cross-milling and cross-drilling capabilities, meaning parts are ejected from the machine fully finished, without the need for any secondary operations. In this way, sliding-heads offer a reduction in cycle time over traditional lathes giving you the associated benefit of a reduction in cost.

In-house we are able to offer:

In-house we are able to offer:

| Tumbling A method of mechanical de-burring, using abrasive ceramic media — usually Alumina shaped stones to rub off any sharp edges. We can also use finer alumina to achieve a polished finish if needed. |

| Bead Blasting Often used on implantable Titanium as the body fuses or grows better around bead blasted parts. We can also use coarse media to roughen surfaces to assist surgeons with a coarser surface to grip parts. |

| Engraving We can engrave details such as part numbers onto parts, or traceability information such as material heat numbers, or even company logos. The list is pretty much endless! |

| Angle Hole Drilling Straight forward holes both axially or cross holes are straight forward but we can also drill holes at angles if required — such as for spray nozzles. |

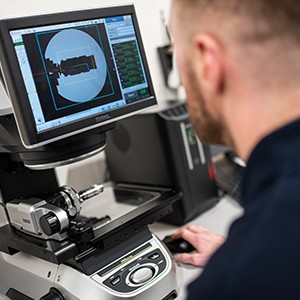

| Measuring As we make ultra-precise parts to within 10 microns, we need to be able to measure them to check and confirm dimensions throughout the entire batch. |

| Inspection We typically adopt AQL sampling for each order machined, but may go beyond the requirements of AQL depending on the criticality of the component’s dimensions. |

We have been manufacturing parts since 2006 and our forte is stainless steel - in fact, 75-80% of the components we make are in stainless materials.

We have experience manufacturing from a wide variety of metals including:

We have experience manufacturing from a wide variety of metals including:

Stainless Steels

Mild Steels

Tool Steel

Aluminium

Brass

Bronze

Copper

Inconel Alloys

Titanium

Did you know we also machine plastics?

Nylon 6 (PA 6)

Nylon 66 (PA 66)

Acetal (POM C and POM H)

Delrin®

Radel®

PEEK™

Please contact the office if the material you require is not listed.